Thursday, 29 April 2010

Overall review of the whole project

On the project

We spilted this project into three area at the beginning. Programming, circuit and the physical components (wheels, gears, chassis). I was mainly involved in the program and the chassis bit.

Programming

Before Easter, Park and me started to draft the program. We break it down into parts. Basically, 4 functions are required. Power on/off, turn left/right, walk in stright line and reverse. We did some simulation in PICAXE but unfortunately I did not save it since that was the very first draft and that is it really before Easter.

Chassis

We disscused on this for kind of long because we have been changing our idea quite often before. Originally, I was about to bring a box-shaped chassis back. Well, the volcano in Iceland erupted. So, my fellow groupmate decided to get something better, meccano.

After all, it is such a shame that I could not take part in the assembling part, and again, I would like to thanks my groupmates. Althought it did not make it through the test, I can see we all learnt something from this project.

Wednesday, 28 April 2010

possible project improvements: personal opinion

- Power supply - As a group we found that at 4.5v, the buggy was vastly underpowered even with a light chassis.

- 2-pole DC motors - The motors supplied, basically lead to the demise of our project. we were under the assumption that all the contents of the toolkit were functioning 100% correctly, this was not the case. Some groups were having problems with the motors circuit, but both our motors had bad connections.

- Wheels - one of our wheels had a very large hole, meaning the axel and hole fit was too loose. this lead to the axel rotating, but the wheel remaining stationary.

- Planning - as a group we should have left more time for the atual testing of buggy, once constructed.

- Prioritising - the four main parts of this project were the chassis, program, circuitry, testing. we focused on the programming side for far too long, meaning the tasks were left till later.

Project demonstration: reflection

Over the holiday period, due to the icelandic ash caused by the volcano, our final chassis was stuck with our chassis designer in Hong Kong! This meant we had to create a new chassis before our circuit and program could be tested. Before and during the holiday period, as a group we were focussed on the programming and left the chassis till the end which in hindsight was definetly a bad idea (although who knew about the volcano problem prior to it errupting?).

TEST DAY

We had just completed everything by monday night, and we only needed to fine tune the chassis which we would have done on the day. 2 hours before the demonstration, our buggy had completly stoped working. this was due to one motor failing. During the duration of the project, we constantly had problems with the two motors which were supplied. We first thought there was a problem with our circuit, then we thought it could be the program and finally the sensors. The batteries were also replaced but with no luck.

After ruling all these out in the fault diagnosing process, we found that the cables connected to the reverse of the motors were to blame. It was due to a bad connection as if they were moved about, the cogs in the motor would 'flicker' into life.

As no replacement motors were available, we had to solder the wires to improve the connection. Fixing the actual problem was relatively fast once a soldering iron was sourced. The actual fault diagnosing was very time consuming. Once both motors were soldiered and the wires replaced, we encountered a short circuit. I am not sure how this could have happened but even the lecturer confirmed our suspicion.

As no replacement motors were available, we had to solder the wires to improve the connection. Fixing the actual problem was relatively fast once a soldering iron was sourced. The actual fault diagnosing was very time consuming. Once both motors were soldiered and the wires replaced, we encountered a short circuit. I am not sure how this could have happened but even the lecturer confirmed our suspicion.

Tuesday, 27 April 2010

Testing Of The buggy

Problem?

The problem in my view was the connection leading to the motor . We tried to solder it many times and as we pressed on the blue wired connection, the motor would start to run. We tried everything , however, i personally think the batteries were accidentally left connected when trying to solder. This may have short circuited the buggy as we were in a desperate rush to atleast get the buggy moving again just before the test.

What would be done differently if i was to do this project again ..

I would stick to simple circuitry like the one which we had to rebuilt to. I would leave a lot more time to test the buggy for following the line and would want do the connections for the wires as strong as possible the first time around.

What was suprising about the project ?

One definate thing i found suprising was how many times the buggy defunctions . This is what i would take into consideration in future project. Everyday there was something which was failing, if not one thing, it was another. It has been a true practical learning experience that theory in reality does not always compute.

Technical Problems / Improvements

Two LDR's were placed on either side of the black line. In our design, especially from the pictures of our design, if both read light, the buggy would go forward ( which can be seen from the programming aswell. If one read darkness, the buggy would turn. We got to test this out , however, the testing was cut short as we had a motor problem near the time of testing. However, When the LDR's were covered ( with paper) which can be seen from our buggy pictures posted earlier, the buggy did follow the line better. The LDR'S were paried with LED's . This was due to the fact that as the LED went over the black line, less light would be reflected to the LDR. Each LDR was paired with an LED and covered in black paper so that it had a control light setting. As the LED moved over the black line it would reflect less light into the LDR. An improvement to the system would be to have a third LDR as we originally planned which would always be exposed to darkness. This would have been the middle LDR and would have made sure out buggy would not have strayed off the line. In addition, more could have been done with the paper cover of the LDR's to stop light comming in. This could have been made more stylish and more effective, however, we found this was not possible due to our own lack of time management.

Friday, 23 April 2010

Funtioning Of The Chassis.

Changing of Wires

There was no result in the functioning of the right motor.

We also connected the wires to the actual motor to see if the motor was not damaged. The wheel at this point did rotate meaning it was something in the circuitry ( which we doubted ), or the connection of the wires was not strong via the soldering.

When we re soldered the wires to the right motor , it started to work. This stage can be seen in the video below.

Finally Working Again

We then connected the circuitry back up to the chassis to see if the power of the right motor was enough to drive the chassis forward again. The video of this can be seen below.

Moving Again

We can now finally configure the chassis to the right setting of the LDR's to make the buggy follow the line !

Hopefully you can all meet me tommorow so we can get this done.

Tuesday, 20 April 2010

Building & Development Of The Chassis

I first started off by building the main body of the chassis which can be seen from the picture above. It seemed to be the strongest way of building the base.

The progression of the chassis can be seen from above as i added a diagonal strip and attached it to the main body to give the circuitry some protection from falling out and this also made the body of the chassis stronger. The strip you can see at the front is for the rotation of the front wheel .

Monday, 19 April 2010

Completed Programming

readadc 1, b1

readadc 2, b2

select case b1

case 78 to 255 ; LDR doesn't detect light

low 1

high 2

case 0 to 77 ; LDR detects light

high 1

low 2

end select

select case b2

case 60 to 255 ; LDR does not detect any light

low 3

high 4

case 0 to 59 ; LDR does detect light

high 3

low 4

end select

debug b1

debug b2

goto main

Sunday, 18 April 2010

Completion of Circuitry

The old circuitry which was built by james worked, however, when trying to make the command system work with the circuitry, we found it hard. This was due to the fact that the circuitry had 3 LDR's and 3 LED's , and our command system was suited to 2 LDRS and 2 LED's . I could have modified the system, however i was more comfortable modifying the circuitry . Below is a picture of the circuitry which was made by James.

Old circuitry

Saturday, 17 April 2010

Meeting 3 ( 17/04 /2010)

- The chassis has been made and the circuitry is complete .

- The program nearly works with the circuitry but for some reason the chassis is not functioning the way we would want it to . There seems to be some sort of problem , hence over the next week we need to work together to see what the problem is and to make the chassis work .

Friday, 16 April 2010

Advanced Command system

main:

readadc 1, b1

readadc 2, b2

select case b1

case 60 to 255

low 2

high 1

case 0 to 59

high 2

pause 600

low 1

end select

select case b2

case 60 to 255

low 4

pause 200

high 3

case 0 to 59

high 4

low 3

end select

debug b1

debug b2

goto main

Command Development

main:

readadc 1, b1

readadc 2, b2

select case b1

case 60 to 255

low 2

high 1

case 0 to 59

high 2

wait 3

low 1

end select

select case b2

case 60 to 255

low 4

wait 3

high 3

case 0 to 59

high 4

low 3

end select

debug b1

debug b2

goto main

As you can see, there are onloy 2 case statements. One for one LDR and the other is for the second one. The circuitry has 3 LDR , therefore, the circuitry either needs to be modified , or the command need to be modified .

Thursday, 15 April 2010

Full view of circuitry

Photos of the circuit

Circuit Diagram

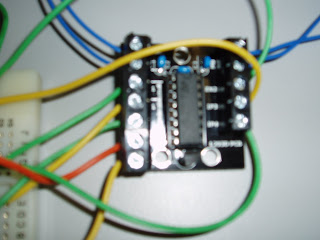

Photos of the motor board

The top two blue lines on each sides are connected to the motors.

The bottom red and yellow on the left are the positive and ground rails respectively.

The green lines below the motor lines are the enable lines, 3rd down on each side.

The two remaining on each sides are from the output of the chip which control the motors direction

Wednesday, 14 April 2010

Body Of the chassis

Wednesday, 7 April 2010

Resistor reference chart

Tuesday, 6 April 2010

Initial command

main:

switchstate = pin1

debug switchstate

goto work1

if input7 is on then work1

end

work1:

if input1 is on and input2 is on and input6 is on then go_f

if input2 is on and input1 is on then go_l

if input6 is on and input1 is on then go_r

goto go_s

go_f: let pins = %10100000

goto main

go_l: let pins = 100000

goto main

go_r: let pins = %10000000

goto main

go_s: let pins = %01000000

goto main